Сухое молокоИз молока, козьего молока и других млекопитающих в качестве сырья, после стерилизации, разделения сливок (в зависимости от требуемого типа молока), концентрации, сушки в порошок, с портативностью и антикоррозийностью.

На сегодняшний день молочный порошок получил широкое применение. Как правило, сухое молоко делится на цельное, обезжиренное и смесь. Лучшие молочные смеси на рынке - это различные виды специальных детских смесей. У нас также есть линия по производству детских смесей.

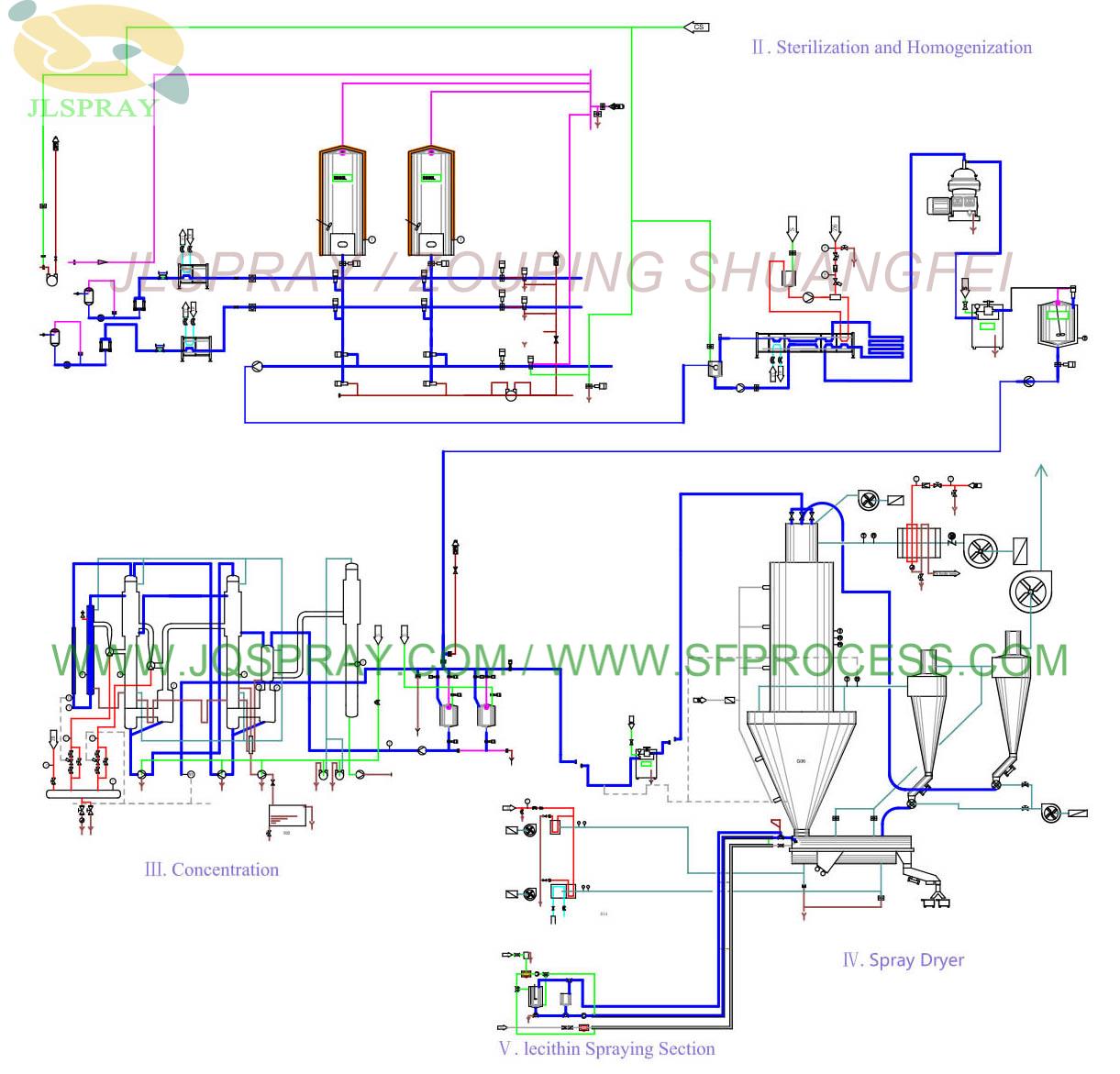

Как правило, линия по производству сухого молока включает в себя компоненты приема, предварительной обработки, обогащения, сушки и упаковки исходного молока. В практической конфигурации, как правило, включают CIP и системы коммунального снабжения.

i. Сбор сырого молока

Молоко собирают с разных молочных ферм, фильтруют, дегазируют, охлаждают, а затем хранят в банках с молоком. Как правило, молоко собирают ежедневно, а это означает, что емкостей для хранения молока должно хватить на один день производства.

Ии. Предварительная обработка

Предварительная обработка свежего молока включает бактерицидную обработку, разделение сливок, гомогенизацию и эмульсию.

Чтобы обеспечить здоровье молока, перед его предварительной обработкой его следует дезинфицировать. Бактерициды обычно используют пастеризационную машину, также можно использовать ультравысокотемпературную стерилизацию, ультравысокотемпературное стерилизованное молоко, но потеря питательных веществ велика.

После стерилизации, в соответствии с требованиями продукта, свежее молоко отделяется. Разделение сливок может быть продано непосредственно на рынке в другие пищевые отрасли, такие как хлеб, производство тортов и дальнейшая переработка в безводные сливки.

Дальнейшая обработка перед молочной формулой осуществляется путем разделения сливок, гомогенизации и эмульсии, чтобы обеспечить последовательное качество продукта и иметь несколько специальных питательных веществ (с добавлением различных пищевых компонентов), таких как детская смесь и старческое молоко.

iii. Концентраторы

Чтобы сократить инвестиции и сэкономить энергию, необходимо концентрировать молоко перед сушкой. В зависимости от свойств молока концентрация применима к многофункциональному мембранному испарителю.

Многофункциональный падающий испаритель - это новый тип концентратора, в зависимости от конфигурации, теоретически 1 кг пара может испарять 3 - 5 кг воды. На практике он несколько ниже.

По сравнению с сухим оборудованием, испарители недорогие, инвестиции низкие, энергосберегающие.

iv. Сухость

Сырое молоко нужно сушить в порошок. Могут работать как сушилки для опрыскивания под давлением, так и сушилки для центробежного распыления, но продукты, производимые сушилками для опрыскивания под давлением, имеют большую зернистость, лучшую текучесть и хорошую растворимость, поэтому сушилки для опрыскивания под давлением широко используются в этом процессе.

Система нагрева распылительной сушилки может быть отделена от других систем отопления для увеличения производственных мощностей и снижения энергопотребления.

v.CIP Системы

Пищевая техника нуждается в регулярной очистке для обеспечения безопасности и здоровья продуктов. Ручная очистка тратит много времени и энергии. Устройства для очистки, предоставляемые нашей компанией, находятся на месте, что помогает сэкономить рабочую силу, получить лучший эффект очистки, избегая ручной очистки, чтобы принести бактерии.

vi. Вспомогательные системы

Мы предоставляем упаковочные машины, коммунальные системы снабжения и другие необходимые системы, такие как охлаждающая вода, замороженная вода, электричество, пар, подача сжатого воздуха по запросу клиента.

Клиенты также могут связаться с местными поставщиками. Мы окажем необходимую поддержку.

Спецификация | Молоко - 1000 | Молоко - 2000 | Молоко - 3000 | Молоко - 5000 | Молоко - 8000 | Молоко - 10000 |

Номинальный выход (kg / h) | 1, 000 | 2, 000 | 3, 0000 | 5, 000 | 8, 000 | 10, 000 |

Годовая производительность (8000 часов / год) (тонна / год) | 8, 000 | 16, 000 | 24, 000 | 40, 000 | 64, 000 | 80, 000 |

Требуемая площадь (м2) | 300-400 | 450-550 | 500-600 | 600-700 | 800-900 | 950 - 1050 |

Коэффициент сбора продукции | 98 - 99,5% (в зависимости от спецификаций, URS и технических параметров) | |||||

Окончательное содержание воды (%) | ^ 3% (в зависимости от URS) | |||||

Плотность накопления продукта (Kg / L) | 0.45 - 0.55 (в зависимости от конфигурации, спецификаций и параметров обработки) | |||||

Температура выбросов (°C) | 35 - 45° (в зависимости от конфигурации и URS) | |||||

Топливо | Любое топливо, такое как природный газ, сжиженный нефтяной газ, нефть и уголь, или другое твердое топливо, такое как рисовая оболочка, кокосовая оболочка, | |||||

Примечание: Эти параметры предназначены только для справочных целей и будут изменены в соответствии с URS.