Асептические опрыскивательные сушилки являются основным оборудованием, используемым в фармацевтической промышленности для производства порошка для инъекций. Большинство антибиотиков производится в стерильных распылительных сушилках WPG, таких как сернокислый стрептомицин, сернокислый цинтамицин, сернокислый канамицин и т.д.

В стерильной системе сушки сначала необходимо обеззараживать весь воздух и сырье. Продукты должны собираться в стерильной камере, поэтому жидкий материал может быть доставлен в распылитель только после фильтрации и дезинфекции. Сжатый воздух также должен быть очищен перед использованием (предоставляется пользователем).

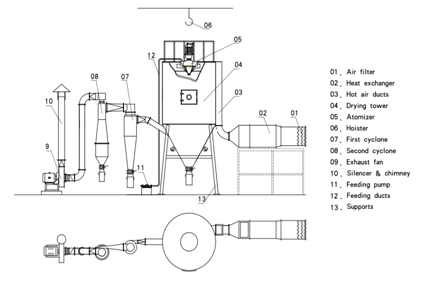

Сухой воздух очищается передним, задним и высокоэффективным воздушным фильтром, нагревается и подается в сушильную камеру распыления. Готовая продукция и воздух будут отделяться через циклонные сепараторы. Сухие продукты собираются и упаковываются на стерильных рабочих станциях, а выхлопные газы сбрасываются после пакетного фильтра.

Асептическая распылительная сушилка WPG с использованием двухпоточного распылителя, простая конструкция, хорошая контактная площадь, равномерное распыление, может соответствовать требованиям стерильного распыления.

В башне установлено устройство для подметания, которое облегчает очистку порошка, прикрепленного к стене.

Предыдущие, задние и высокоэффективные воздушные фильтры используются для очистки горячего воздуха, чтобы получить высококачественный очищенный воздух и соответствовать требованиям GMP.

Фармацевтическая продукция: Экстракты китайской медицины (экстракты трав), лекарственные коллоиды, дрожжи, витамины, антибиотики, амилазы, липаза и так далее.

В основном используется в антибиотиках, таких как сернокислый стрептомицин, сернокислый цинтамицин, сернокислый канамицин и так далее.

Спецификация | WPG - 5 | WPG - 25 | WPG - 50 | WPG - 100 | WPG - 150 | WPG - 200 |

Температура впуска | 140 - 550°C (в зависимости от высушенного продукта и URS) | |||||

Температура выхлопа | 60 - 120°C (в зависимости от высушенного продукта и URS) | |||||

Номинальное количество испарения воды (кг / ч) | 5 | 25 | 50 | 100 | 150 | 200 |

Режим нагрева | Пар высокого давления, или пар + электричество, или любой вид топлива (дизельное топливо, природный газ, сжиженный нефтяной газ или уголь и т.д.), или твердое топливо (любой горючий материал). Просьба уточнить. | |||||

Диаметр сухой башни (мм) | 1100 | 1800 | 2150 | 2560 | 2860 | 3200 |

Внешний размер (m) | 2 × 1.4 × 2.2 | 5 × 3 × 4 | 6 × 4 × 5 | 8 × 4 × 6 | 8 × 5 × 7 | 10 × 5 × 8 |

Производство продукции | 95 - 99,9% В зависимости от характеристик продукта и конфигурации | |||||

Спецификация | WPG - 300 | WPG - 500 | WPG - 1000 | WPG - 2000 | WPG - 5000 | WPG - 15 000 |

Температура впуска | 140 - 550°C (в зависимости от высушенного продукта и URS) | |||||

Температура выхлопа | 60 - 120°C (в зависимости от высушенного продукта и URS) | |||||

Номинальное количество испарения воды (кг / ч) | 300 | 500 | 1000 | 2000 | 5000 | 15000 |

Режим нагрева | Пар высокого давления, или пар + электричество, или любой вид топлива (дизельное топливо, природный газ, сжиженный нефтяной газ или уголь и т.д.), или твердое топливо (любой горючий материал). Просьба уточнить. | |||||

Диаметр сухой башни (мм) | 3600 | 4300 | 6000 | 7600 | 10000 | 18000 |

Внешний размер (m) | Проектирование в соответствии с конфигурацией завода и URS | |||||

Производство продукции | 95 - 99,9% В зависимости от характеристик продукта и конфигурации | |||||

Примечание: Эти параметры предназначены только для справочных целей и будут изменены в соответствии с URS.