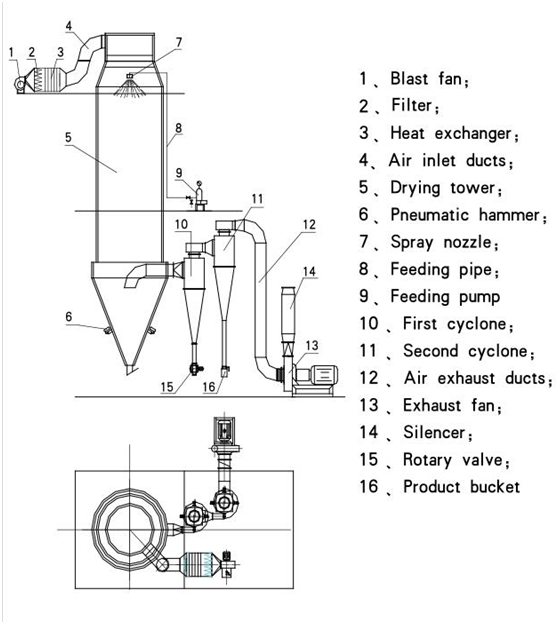

1, соевый белок SPG распылительная сушилка модель: сушка с использованием опрыскивания под давлением. Амортизатор был изменен на насос высокого давления для обеспечения высокого давления.

2. Тип выбросов: конечный продукт собирается из сепаратора циклона, а не со дна сушильной башни. Поскольку соевый протеиновый порошок плохо подвижен и легко прилипает к конической части сухой башни, цепные скребки должны быть установлены на конической части, чтобы соскребать прилипающий порошок. Собранные продукты будут доставлены в упаковочную комнату пневматическим путем и охлаждаться до комнатной температуры во время пневматического транспорта.

Этот метод сушки защищает активные ингредиенты соевого белкового порошка от повреждения.

4. Система распыления использует несколько сопел. Чтобы избежать перекрестного контакта распылителя, область распыления сопла специально спроектирована как полукруглая структура, а сопла высокого давления обычно являются американскими брендами.

5. Во избежание чрезмерного давления в сухих башнях на вентиляционных отверстиях установлены вакуумные защитные устройства.

6. Распределители горячего воздуха, изготовленные с использованием специальных технологий. Чтобы избежать отклонения скорости воздушного потока, распределитель горячего воздуха делится на несколько воздухозаборников, каждый из которых имеет контрольный клапан, так что горячий ветер равномерно спирально входит в сухую башню, тем самым гарантируя эффективное использование тепла и материал не приклеивается к стенке.

Соевый белок, или соевый белок, не легко распыляется из - за его высокой вязкости. С обычным высокоскоростным центробежным распылителем он плохо распыляется. Внедрение распылительной сушилки с атмосферным давлением, из - за ее высокой высоты, инвестиции значительно увеличились. Кроме того, температура подачи материала очень высока. В соответствии с этими характеристиками комбинированные распылительные сушилки специально спроектированы: с центробежными распылительными сухими башнями (высота короткая, диаметр большой), распределением центробежных воздухозаборников (улитка с распределителем горячего воздуха) и соплами давления (эффект центробежного распыления не очень хорош, продукт не легко растворяется, поэтому мы выбираем распыление высокого давления). Используя эту структуру, инвестиции намного ниже, и в то же время могут соответствовать относительным требованиям продукта.

- Да.Пищевая промышленность: Соевый белок, цельное сухое молоко, обезжиренное молоко, какао - молоко, заменители молока, яичный белок (желток) и другие подмышечные прионы, овес, куриный сок, растворимый чай, ароматическое мясо, белки, соя, арахисовый белок, белковый тимьян. Кукурузный сироп, кукурузный крахмал, глюкоза, пектин, солодовый сахар, сорнякат калия, тыквенный порошок, растворимый кофе, безмолочное молоко и т.д.

Спецификация | СПГ - 25 | СПГ - 50 | СПГ - 100 | СПГ - 150 | СПГ - 200 | СПГ - 300 |

Температура впуска | 140 - 550°C (в зависимости от высушенного продукта и URS) | |||||

Температура выхлопа | 60 - 120°C (в зависимости от высушенного продукта и URS) | |||||

Номинальное количество испарения воды (кг / ч) | 25 | 50 | 100 | 150 | 200 | 300 |

Режим нагрева | Пар высокого давления, или пар + электричество, или любой вид топлива (дизельное топливо, природный газ, сжиженный нефтяной газ или уголь и т.д.), или твердое топливо (любой горючий материал). Просьба уточнить. | |||||

Диаметр сухой башни (мм) | 1200 | 1400 | 1600 | 2200 | 2600 | 3200 |

Внешний размер (m) | 5 × 4 × 12 | 6 × 4 × 13 | 6 × 4 × 15 | 8 × 4.5×19 | 10 × 5 × 20 | 12 × 6 × 22 |

Производство продукции | 95 - 99,9% В зависимости от характеристик продукта и конфигурации | |||||

Спецификация | СПГ - 500 | СПГ - 1000 | СПГ - 2000 | СПГ - 5000 | СПГ - 100000 | СПГ - 15 000 |

Температура впуска | 140 - 550°C (в зависимости от высушенного продукта и URS) | |||||

Температура выхлопа | 60 - 120°C (в зависимости от высушенного продукта и URS) | |||||

Номинальное количество испарения воды (кг / ч) | 500 | 1000 | 2000 | 5000 | 10000 | 15000 |

Режим нагрева | Пар высокого давления, или пар + электричество, или любой вид топлива (дизельное топливо, природный газ, сжиженный нефтяной газ или уголь и т.д.), или твердое топливо (любой горючий материал). Просьба уточнить. | |||||

Диаметр сухой башни (мм) | 3800 | 5500 | 7300 | 10000 | 14500 | 17500 |

Внешний размер (m) | Проектирование в соответствии с конфигурацией завода и URS | |||||

Производство продукции | 95 - 99,9% В зависимости от характеристик продукта и конфигурации | |||||

Примечание: Эти параметры предназначены только для справочных целей и будут изменены в соответствии с URS.